How does optical bonding work?

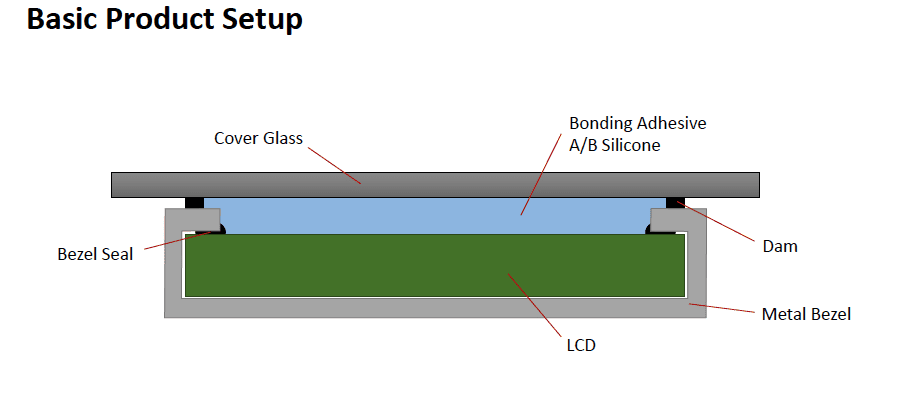

Optical bonding is a method of adhering a layer of silicone in between the bezel seal and the cover glass.

Optical bonding is a very complex process, but has many effective benefits.

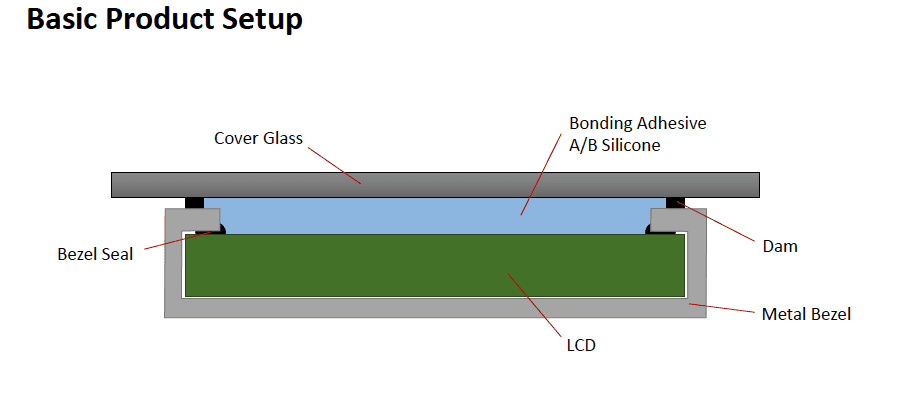

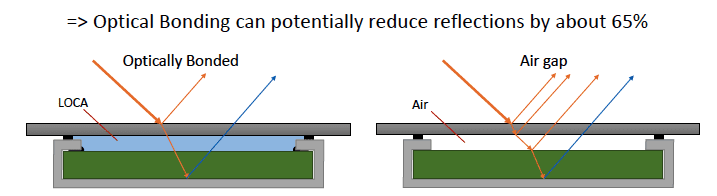

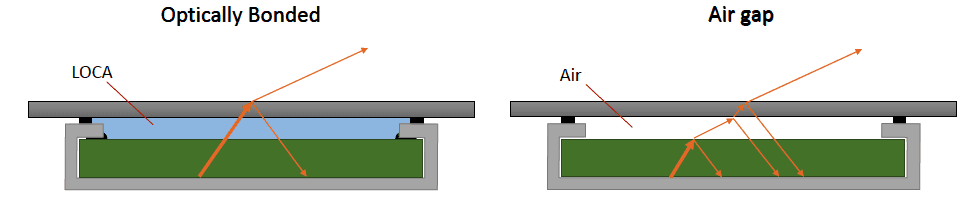

Decrease Reflection

When light reflects from one material to another there is something produced called a refraction index and about 4 % of the light will be reflected. Optical bonding can eliminate or drastically decrease this reflection issue.

Increase Brightness

A glass cover increases on top of the display decreased brightness due to reflection from the backlight and glass transmission. Optical bonding helps combat this increasing brightness on average by about 10 %.

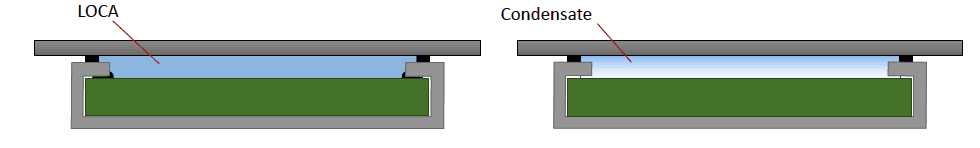

Decrease Fogging

Optical bonding can tremendously decrease water build up and humidity that can form in the air gap between the top glass and panel. Deviations in temperature or air pressure can cause humidity to condense on surfaces, especially in sealed systems with little or no air flow.

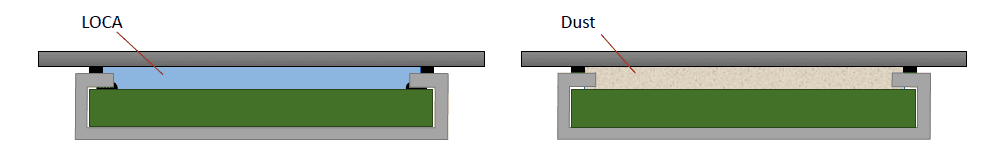

Dust Proof

Optical bonding can illuminate the concern or dust or dirt build up over time in the panel in harsh or industrial environments.

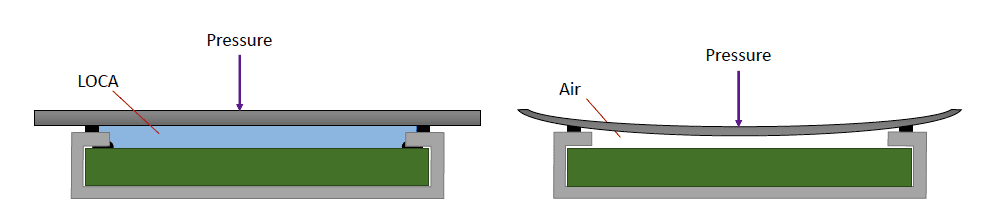

Ruggedized Glass

Optical Bonding can increase the elasticity to absorb shocks and increase panel strength by providing added support.

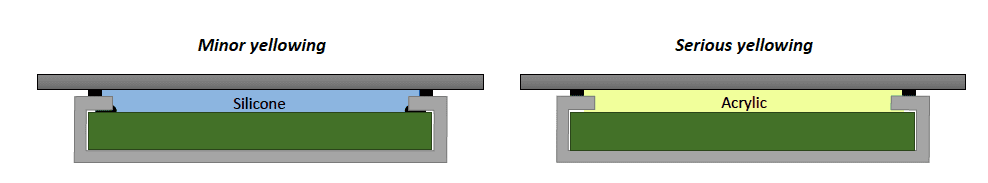

Increased Clarity

Over time panels in UV light can decrease clarity and start to yellow. Optical bonding decreases the level of yellowing over other substrates including acrylic.

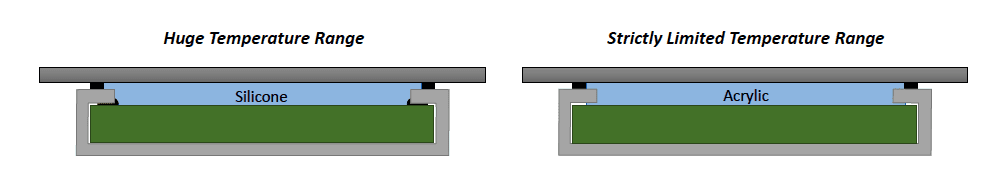

Temperature control

Optical bonding remains stable over high and low temperature changes. While materials as Acrylics can obtain irreversible damage, bonding silicone can crystalize and revert back to its original form.

Contact Faytech North America today to answer all your questions !